FDC2112DNTT - English Editing Encyclopedia Entry

Product Overview

Category

The FDC2112DNTT belongs to the category of integrated circuits (ICs).

Use

This IC is primarily used for sensing and measuring liquid levels in various applications.

Characteristics

- High accuracy and precision in liquid level detection.

- Low power consumption, making it suitable for battery-powered devices.

- Compact size and lightweight design.

- Wide operating voltage range.

- Excellent noise immunity.

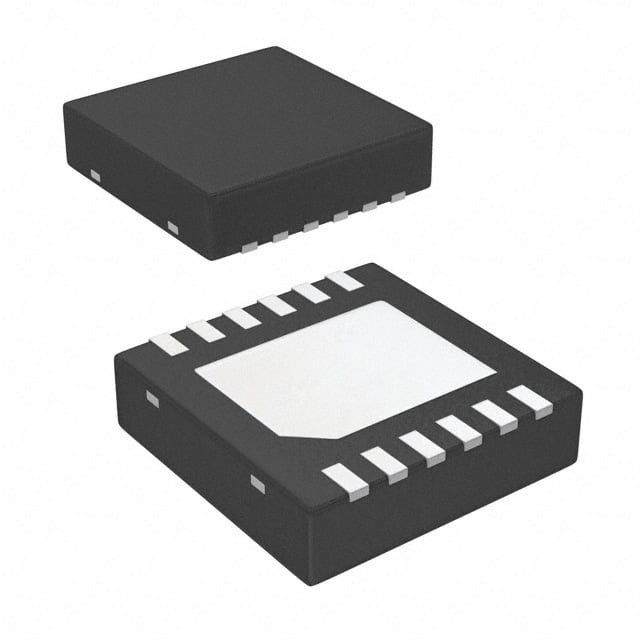

Package

The FDC2112DNTT is available in a small outline no-lead (SON) package.

Essence

The essence of the FDC2112DNTT lies in its ability to accurately measure liquid levels with minimal power consumption.

Packaging/Quantity

The FDC2112DNTT is typically packaged in reels containing 2500 units per reel.

Specifications

- Supply Voltage: 2.7V to 3.6V

- Operating Temperature Range: -40°C to +85°C

- Resolution: 28 bits

- Output Interface: I2C

- Maximum Capacitance Change: ±1pF

- Conversion Time: 10ms

Detailed Pin Configuration

The FDC2112DNTT features a total of 8 pins, each serving a specific purpose:

- VDD: Power supply pin (2.7V to 3.6V).

- GND: Ground reference pin.

- SDA: Serial data input/output pin (I2C interface).

- SCL: Serial clock input pin (I2C interface).

- ADDR: Address selection pin.

- INTB: Interrupt output pin.

- TEST: Test mode pin.

- NC: No connection pin.

Functional Features

- High-resolution liquid level sensing.

- Automatic compensation for temperature variations.

- Built-in self-calibration mechanism.

- Configurable interrupt output for level threshold detection.

- Low power consumption in sleep mode.

Advantages and Disadvantages

Advantages

- High accuracy and precision in liquid level measurement.

- Wide operating voltage range allows for versatile applications.

- Compact size enables integration into space-constrained devices.

- Excellent noise immunity ensures reliable performance.

- Self-calibration feature reduces the need for manual calibration.

Disadvantages

- Limited to liquid level sensing applications only.

- Requires an external microcontroller for data processing and interpretation.

- Relatively higher cost compared to traditional liquid level sensors.

Working Principles

The FDC2112DNTT utilizes the principle of capacitive sensing to measure liquid levels. It employs a pair of electrodes that form a capacitor with the liquid being sensed. As the liquid level changes, the capacitance between the electrodes also varies. The IC measures this capacitance change and converts it into a digital value using its internal analog-to-digital converter (ADC). By analyzing the digital value, the liquid level can be accurately determined.

Detailed Application Field Plans

The FDC2112DNTT finds extensive application in various industries, including:

- Automotive: Fuel level monitoring, coolant level detection.

- Industrial: Tank level measurement, liquid flow control.

- Medical: Infusion pump liquid level sensing, blood analyzer fluid detection.

- Consumer Electronics: Water level monitoring in washing machines, coffee machines.

Detailed and Complete Alternative Models

- FDC2214DNTT: Similar to FDC2112DNTT but with additional channels for multi-level sensing.

- FDC1004DNTT: Capacitive sensing IC with broader application scope beyond liquid level measurement.

- AD7745ACPZ: Another high-resolution capacitive sensing IC suitable for liquid level detection.

In conclusion, the FDC2112DNTT is a highly accurate and low-power integrated circuit designed for liquid level sensing applications. Its compact size, wide operating voltage range, and excellent noise immunity make it an ideal choice for various industries. However, it requires an external microcontroller for data processing and interpretation. Alternative models such as the FDC2214DNTT, FDC1004DNTT, and AD7745ACPZ offer similar functionalities with slight variations to cater to different requirements.

技術ソリューションにおける FDC2112DNTT の適用に関連する 10 件の一般的な質問と回答をリストします。

Sure! Here are 10 common questions and answers related to the application of FDC2112DNTT in technical solutions:

Q: What is FDC2112DNTT? A: FDC2112DNTT is a highly integrated, high-precision capacitance-to-digital converter designed for use in applications such as proximity sensing, level sensing, and touch sensing.

Q: What is the operating voltage range of FDC2112DNTT? A: The operating voltage range of FDC2112DNTT is typically between 2.7V and 3.6V.

Q: How many channels does FDC2112DNTT support? A: FDC2112DNTT supports two channels, allowing simultaneous measurement of two different capacitive sensors.

Q: What is the resolution of FDC2112DNTT? A: FDC2112DNTT has a resolution of up to 28 bits, providing high accuracy in capacitance measurements.

Q: Can FDC2112DNTT be used for non-contact distance measurement? A: Yes, FDC2112DNTT can be used for non-contact distance measurement by measuring changes in capacitance caused by the presence or absence of an object.

Q: Is FDC2112DNTT suitable for liquid level sensing applications? A: Yes, FDC2112DNTT is suitable for liquid level sensing applications as it can accurately measure changes in capacitance caused by the presence or absence of liquid.

Q: Does FDC2112DNTT require external calibration? A: No, FDC2112DNTT has built-in calibration capabilities, eliminating the need for external calibration.

Q: Can FDC2112DNTT be interfaced with microcontrollers? A: Yes, FDC2112DNTT can be easily interfaced with microcontrollers using standard communication protocols such as I2C or SPI.

Q: What is the maximum sampling rate of FDC2112DNTT? A: The maximum sampling rate of FDC2112DNTT is typically 1000 samples per second.

Q: Are there any evaluation boards available for FDC2112DNTT? A: Yes, Texas Instruments provides an evaluation board for FDC2112DNTT, which allows easy testing and development of applications using this sensor.

Please note that these answers are general and may vary depending on the specific implementation and requirements of your technical solution.