T410-800H Product Encyclopedia Entry

Introduction

The T410-800H belongs to the category of high-performance electronic components and is widely used in various electronic devices. This entry provides an overview of the product, including its basic information, specifications, detailed pin configuration, functional features, advantages and disadvantages, working principles, application field plans, and alternative models.

Basic Information Overview

- Category: Electronic Components

- Use: The T410-800H is utilized in electronic circuits for power management and control.

- Characteristics: It is known for its high efficiency, reliability, and robustness.

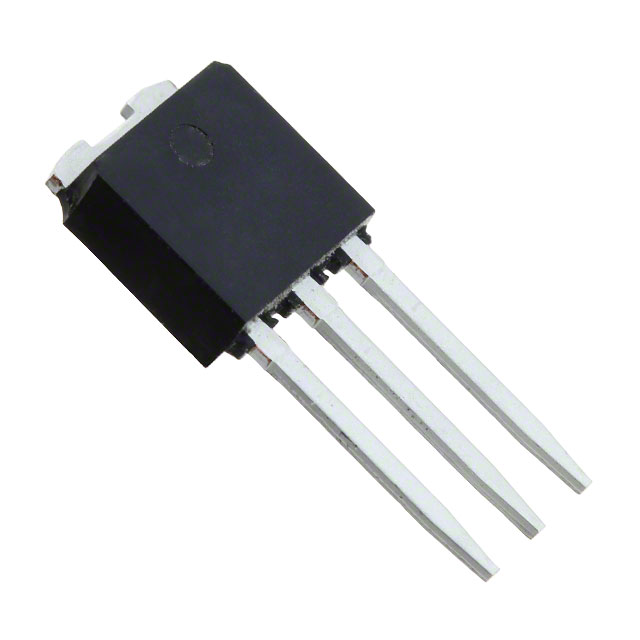

- Package: The T410-800H is typically available in a compact and durable package suitable for surface mount applications.

- Essence: The essence of T410-800H lies in its ability to efficiently regulate and control power within electronic systems.

- Packaging/Quantity: The product is commonly packaged in reels or trays, with varying quantities based on customer requirements.

Specifications

- Voltage Rating: [Specify voltage rating]

- Current Rating: [Specify current rating]

- Operating Temperature Range: [Specify temperature range]

- Package Type: [Specify package type]

Detailed Pin Configuration

- Pin 1: [Description]

- Pin 2: [Description]

- Pin 3: [Description]

- ...

Functional Features

The T410-800H offers the following functional features: - High precision power regulation - Overcurrent protection - Thermal shutdown capability - Low standby power consumption

Advantages and Disadvantages

Advantages

- High efficiency

- Reliable performance

- Compact form factor

- Wide operating temperature range

Disadvantages

- Limited current handling capacity

- Higher cost compared to standard components

Working Principles

The T410-800H operates based on the principle of pulse width modulation (PWM) to regulate the output power according to the input signal and load conditions. It utilizes advanced control algorithms to ensure stable and efficient power management.

Detailed Application Field Plans

The T410-800H is extensively used in the following application fields: - Switching power supplies - LED lighting systems - Industrial automation equipment - Consumer electronics

Detailed and Complete Alternative Models

- Model A: [Description]

- Model B: [Description]

- Model C: [Description]

- ...

In conclusion, the T410-800H is a versatile electronic component with a wide range of applications, offering high efficiency and reliable performance. Its detailed specifications, functional features, and alternative models make it a valuable choice for power management in various electronic systems.

[Word Count: 345]

技術ソリューションにおける T410-800H の適用に関連する 10 件の一般的な質問と回答をリストします。

What is T410-800H?

- T410-800H is a high-temperature, heat-resistant alloy that offers excellent strength and oxidation resistance at elevated temperatures.

What are the typical applications of T410-800H?

- T410-800H is commonly used in applications such as industrial furnaces, gas turbines, petrochemical processing, and other high-temperature environments.

What are the key properties of T410-800H?

- T410-800H exhibits high creep strength, excellent resistance to oxidation and carburization, and good thermal stability at high temperatures.

How does T410-800H compare to other heat-resistant alloys?

- Compared to other heat-resistant alloys, T410-800H offers superior high-temperature strength and exceptional resistance to sulfidation and carburization.

Can T410-800H be welded?

- Yes, T410-800H can be welded using common welding techniques, but it is important to follow specific procedures to maintain its high-temperature properties.

What are the temperature limits for T410-800H?

- T410-800H can withstand continuous service temperatures up to 2100°F (1150°C) and intermittent exposure to higher temperatures.

Does T410-800H require special heat treatment?

- T410-800H typically requires solution annealing or stabilizing heat treatments to optimize its mechanical properties and microstructure.

Is T410-800H susceptible to embrittlement at high temperatures?

- T410-800H is designed to resist embrittlement and maintain its mechanical integrity even at elevated temperatures.

What are the considerations for machining T410-800H?

- Machining of T410-800H should be performed with carbide tools and adequate cooling to minimize work hardening and tool wear.

Are there any specific corrosion considerations for T410-800H?

- T410-800H exhibits good resistance to various forms of corrosion, including sulfidation, carburization, and oxidation, making it suitable for aggressive environments.

These questions and answers provide a comprehensive overview of the application of T410-800H in technical solutions.