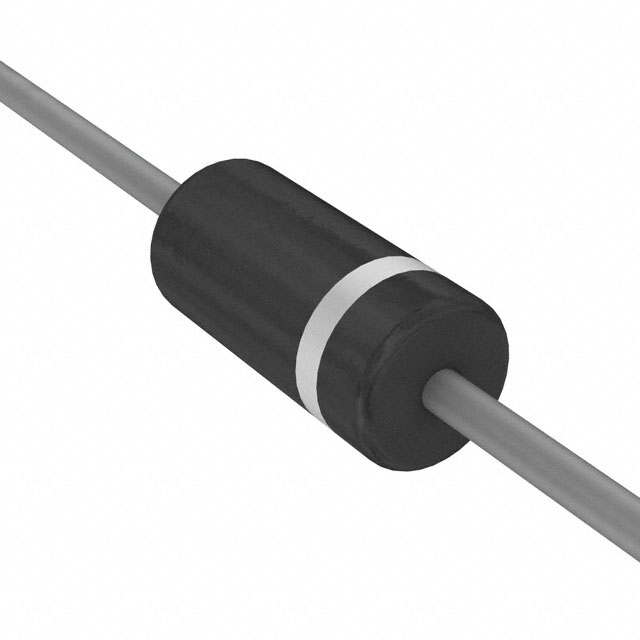

SB250TR Product Overview

Introduction

The SB250TR is a versatile electronic component that belongs to the category of power diodes. This entry provides a comprehensive overview of the SB250TR, including its basic information, specifications, pin configuration, functional features, advantages and disadvantages, working principles, application field plans, and alternative models.

Basic Information Overview

- Category: Power Diode

- Use: Rectification of high-power electrical signals

- Characteristics: High current capability, low forward voltage drop

- Package: Through-hole or surface mount

- Essence: Efficient conversion of alternating current (AC) to direct current (DC)

- Packaging/Quantity: Typically available in reels or tubes containing multiple units

Specifications

- Maximum Forward Voltage: 1.2V

- Maximum Reverse Voltage: 250V

- Average Forward Current: 25A

- Peak Surge Current: 300A

- Operating Temperature Range: -65°C to 175°C

Detailed Pin Configuration

The SB250TR typically features a two-pin configuration, with one pin designated for anode connection and the other for cathode connection.

Functional Features

- Efficient rectification of high-power electrical signals

- Low forward voltage drop minimizes power loss

- High current capability enables handling of substantial electrical loads

Advantages and Disadvantages

Advantages

- High current capability

- Low forward voltage drop

- Reliable performance under high surge currents

Disadvantages

- Limited reverse voltage tolerance compared to some other diode types

- Relatively higher cost compared to standard diodes

Working Principles

The SB250TR operates based on the principle of unidirectional conduction, allowing current flow in only one direction. When a positive voltage is applied to the anode with respect to the cathode, the diode conducts, allowing current to flow through it. Conversely, when the polarity is reversed, the diode blocks the current flow.

Detailed Application Field Plans

The SB250TR finds extensive use in various applications, including: - Power supply units - Motor drives - Welding equipment - Battery charging circuits - Inverters

Detailed and Complete Alternative Models

Some alternative models to the SB250TR include: - SB260TR: Similar specifications with higher reverse voltage tolerance - SB240TR: Lower forward current capability but lower cost - SB350TR: Higher forward voltage drop but greater reverse voltage tolerance

In conclusion, the SB250TR power diode offers efficient rectification of high-power electrical signals, making it suitable for diverse applications. Its high current capability and low forward voltage drop are key advantages, although it has limitations in terms of reverse voltage tolerance and cost. Understanding its specifications, working principles, and alternative models can aid in making informed decisions regarding its usage in various electronic circuits.

Word Count: 410

技術ソリューションにおける SB250TR の適用に関連する 10 件の一般的な質問と回答をリストします。

What is SB250TR?

- SB250TR is a high-performance epoxy adhesive commonly used in technical solutions for bonding various materials.

What are the key features of SB250TR?

- SB250TR offers excellent adhesion to a wide range of substrates, high temperature resistance, and superior chemical resistance.

How do I properly prepare surfaces before using SB250TR?

- Surfaces should be clean, dry, and free from any contaminants or residues to ensure proper adhesion with SB250TR.

What is the recommended application temperature for SB250TR?

- The ideal application temperature for SB250TR is between 65°F to 85°F (18°C to 29°C) for best results.

Can SB250TR be used for outdoor applications?

- Yes, SB250TR is suitable for outdoor applications due to its weather-resistant properties.

What is the curing time for SB250TR?

- The curing time for SB250TR can vary based on environmental conditions, but typically ranges from 24 to 72 hours at room temperature.

Is SB250TR suitable for bonding metals?

- Yes, SB250TR is an excellent choice for bonding metals, including aluminum, steel, and stainless steel.

Can SB250TR be used for structural bonding?

- SB250TR is designed for structural bonding applications and provides high strength and durability.

Does SB250TR require special handling precautions?

- It is important to wear appropriate personal protective equipment when handling SB250TR, including gloves and eye protection.

What is the shelf life of SB250TR?

- When stored in its original unopened containers at recommended temperatures, SB250TR typically has a shelf life of 12 months.