MBR1645: Diode Rectifier

Basic Information Overview

- Category: Diode rectifier

- Use: Rectifying alternating current (AC) to direct current (DC) in electronic circuits

- Characteristics: High efficiency, low forward voltage drop, fast switching speed

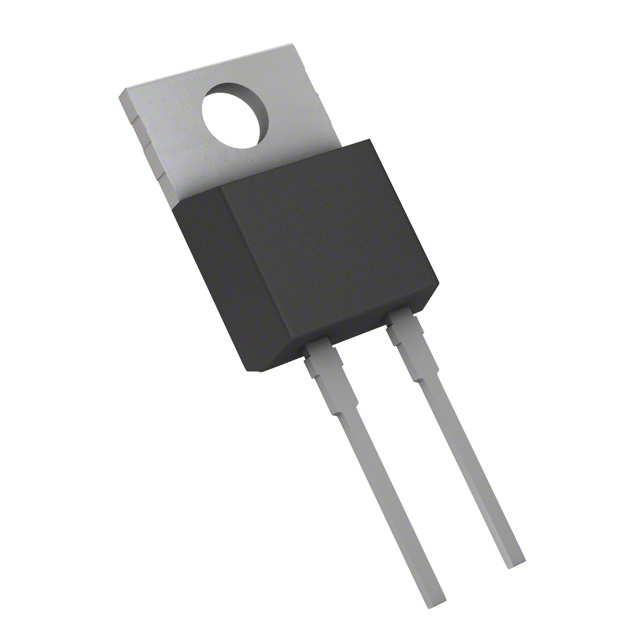

- Package: TO-220AB

- Essence: Efficient and reliable rectification of AC to DC

- Packaging/Quantity: Typically packaged in reels or tubes, quantity varies by manufacturer

Specifications

- Voltage Rating: 45V

- Current Rating: 16A

- Forward Voltage Drop: 0.75V at 8A

- Reverse Leakage Current: 10μA at 25°C

Detailed Pin Configuration

The MBR1645 has a standard TO-220AB package with the following pin configuration: 1. Anode 2. Cathode

Functional Features

- High current capability

- Low power loss

- Fast reverse recovery time

Advantages and Disadvantages

Advantages

- High efficiency

- Low forward voltage drop

- Fast switching speed

Disadvantages

- Higher cost compared to standard diodes

- Larger physical size due to higher current rating

Working Principles

The MBR1645 operates on the principle of rectification, allowing current to flow in only one direction, from anode to cathode, when a forward voltage is applied.

Detailed Application Field Plans

The MBR1645 is commonly used in: - Power supplies - Battery chargers - Motor drives - Solar panels

Detailed and Complete Alternative Models

- MBR1660: 60V, 16A diode rectifier

- MBR20100: 100V, 20A diode rectifier

- MBR3045: 45V, 30A diode rectifier

In conclusion, the MBR1645 diode rectifier offers high efficiency and fast switching speed, making it suitable for various applications such as power supplies, battery chargers, motor drives, and solar panels. While it may have a higher cost and larger size compared to standard diodes, its performance and reliability make it a preferred choice in many electronic circuits.

[Word count: 294]

技術ソリューションにおける MBR1645 の適用に関連する 10 件の一般的な質問と回答をリストします。

Sure, here are 10 common questions and answers related to the application of MBR1645 in technical solutions:

Q: What is MBR1645? A: MBR1645 is a Schottky barrier rectifier diode with a maximum average forward current of 16A and a reverse voltage of 45V.

Q: What are the typical applications of MBR1645? A: MBR1645 is commonly used in power supplies, converters, and other electronic equipment where high efficiency and low forward voltage drop are required.

Q: What is the forward voltage drop of MBR1645? A: The forward voltage drop at 8A is typically around 0.65V for MBR1645.

Q: What is the reverse recovery time of MBR1645? A: The reverse recovery time of MBR1645 is typically 30ns.

Q: Can MBR1645 be used in high-frequency applications? A: Yes, MBR1645 is suitable for high-frequency applications due to its fast switching characteristics.

Q: What is the operating temperature range of MBR1645? A: The operating temperature range of MBR1645 is -65°C to +175°C.

Q: Is MBR1645 RoHS compliant? A: Yes, MBR1645 is compliant with the Restriction of Hazardous Substances (RoHS) directive.

Q: What package type is MBR1645 available in? A: MBR1645 is available in a TO-220AB package.

Q: Can MBR1645 be used in parallel for higher current applications? A: Yes, MBR1645 can be used in parallel to increase the current handling capability in high-current applications.

Q: Are there any specific layout considerations when using MBR1645 in a circuit? A: It is recommended to minimize the length of the traces connecting MBR1645 to reduce parasitic inductance and ensure proper heat dissipation.

I hope these questions and answers are helpful for your technical solutions involving MBR1645. Let me know if you need further assistance!