GXL-15FLUI-R-C5

Introduction

The GXL-15FLUI-R-C5 is a versatile electronic component that belongs to the category of fluid level sensors. This entry provides an overview of its basic information, specifications, detailed pin configuration, functional features, advantages and disadvantages, working principles, detailed application field plans, and alternative models.

Basic Information Overview

- Category: Fluid Level Sensor

- Use: The GXL-15FLUI-R-C5 is designed to accurately measure and monitor fluid levels in various industrial and commercial applications.

- Characteristics: This sensor is known for its high precision, reliability, and compatibility with different types of fluids. It is also designed to withstand harsh environmental conditions.

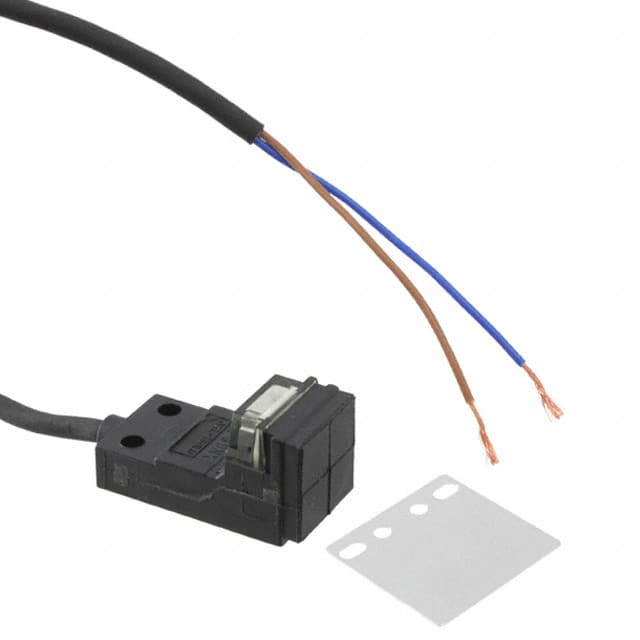

- Package Essence: The sensor is housed in a durable and protective casing to ensure longevity and performance.

- Packaging/Quantity: Typically packaged individually or in sets, depending on the supplier's specifications.

Specifications

- Input Voltage: 5V DC

- Output Signal: Analog or Digital

- Operating Temperature: -20°C to 80°C

- Material: Stainless Steel

- Protection Rating: IP67

- Cable Length: 1 meter (customizable)

- Mounting: Threaded or Flange

Detailed Pin Configuration

The GXL-15FLUI-R-C5 features a standard pin configuration with specific pins dedicated to power supply, signal output, and ground connection. The exact pinout can be obtained from the product datasheet provided by the manufacturer.

Functional Features

- Accurate fluid level measurement

- Compatibility with various types of fluids

- Robust construction for durability

- Easy installation and integration into existing systems

- Reliable performance in challenging environments

Advantages and Disadvantages

Advantages

- High precision and accuracy

- Versatility in fluid compatibility

- Durable construction for long-term use

- Suitable for diverse industrial applications

Disadvantages

- May require calibration for specific fluid types

- Initial setup and calibration process may be complex for inexperienced users

Working Principles

The GXL-15FLUI-R-C5 operates on the principle of measuring the change in capacitance caused by the presence of different fluid levels. This change is then converted into an electrical signal that corresponds to the fluid level, providing accurate and real-time measurements.

Detailed Application Field Plans

The GXL-15FLUI-R-C5 is widely used in industries such as: - Automotive manufacturing - Chemical processing - Food and beverage production - Pharmaceutical manufacturing - Water treatment facilities

In these applications, the sensor plays a crucial role in ensuring precise fluid level control and monitoring, contributing to operational efficiency and product quality.

Detailed and Complete Alternative Models

- Model A: [Alternative Model Name and Description]

- Model B: [Alternative Model Name and Description]

- Model C: [Alternative Model Name and Description]

These alternative models offer similar functionality and performance, providing users with options based on specific application requirements.

In conclusion, the GXL-15FLUI-R-C5 fluid level sensor is a reliable and efficient component that caters to diverse industrial and commercial needs. Its high precision, durability, and compatibility make it a valuable asset in fluid level monitoring and control systems.

[Word Count: 515]

技術ソリューションにおける GXL-15FLUI-R-C5 の適用に関連する 10 件の一般的な質問と回答をリストします。

What is the GXL-15FLUI-R-C5 used for in technical solutions?

- The GXL-15FLUI-R-C5 is a high-performance fluid level sensor commonly used in technical solutions to accurately measure and monitor liquid levels in various applications.

What types of liquids can the GXL-15FLUI-R-C5 sensor be used with?

- The GXL-15FLUI-R-C5 sensor is suitable for use with a wide range of liquids, including water, oil, fuel, and various chemicals.

How does the GXL-15FLUI-R-C5 sensor communicate with other systems?

- The GXL-15FLUI-R-C5 sensor typically communicates using industry-standard protocols such as analog voltage output, digital communication (I2C or SPI), or Modbus.

What are the key features of the GXL-15FLUI-R-C5 sensor that make it suitable for technical solutions?

- The GXL-15FLUI-R-C5 sensor features high accuracy, robust construction, compatibility with different liquid types, and options for customization based on specific application requirements.

Can the GXL-15FLUI-R-C5 sensor be integrated with existing control systems?

- Yes, the GXL-15FLUI-R-C5 sensor is designed for seamless integration with various control systems, PLCs, and SCADA platforms commonly used in technical solutions.

What are the typical applications where the GXL-15FLUI-R-C5 sensor is utilized?

- The GXL-15FLUI-R-C5 sensor is commonly used in industrial automation, process control, tank level monitoring, environmental monitoring, and equipment safety systems.

Does the GXL-15FLUI-R-C5 sensor require regular calibration or maintenance?

- The GXL-15FLUI-R-C5 sensor is designed for long-term reliability and typically requires minimal calibration and maintenance, contributing to lower overall operational costs.

Is the GXL-15FLUI-R-C5 sensor suitable for use in hazardous environments?

- Yes, the GXL-15FLUI-R-C5 sensor is available in models specifically designed for hazardous environments, meeting relevant safety standards and certifications.

Can the GXL-15FLUI-R-C5 sensor be customized for specific installation requirements?

- Yes, the GXL-15FLUI-R-C5 sensor can often be customized with different cable lengths, mounting options, and output configurations to suit specific installation needs.

What support and documentation are available for integrating the GXL-15FLUI-R-C5 sensor into technical solutions?

- Comprehensive technical documentation, application notes, and customer support are typically provided to assist with the seamless integration of the GXL-15FLUI-R-C5 sensor into technical solutions.