EE-SA105

Product Overview

Category: Electronic Component

Use: Signal Amplification

Characteristics: High gain, low noise, compact size

Package: Small outline integrated circuit (SOIC)

Essence: Amplifier IC

Packaging/Quantity: 25 pieces per tube

Specifications

- Supply Voltage: 5V to 15V

- Gain Bandwidth Product: 10MHz

- Input Bias Current: 10nA

- Output Current: 20mA

- Operating Temperature Range: -40°C to 85°C

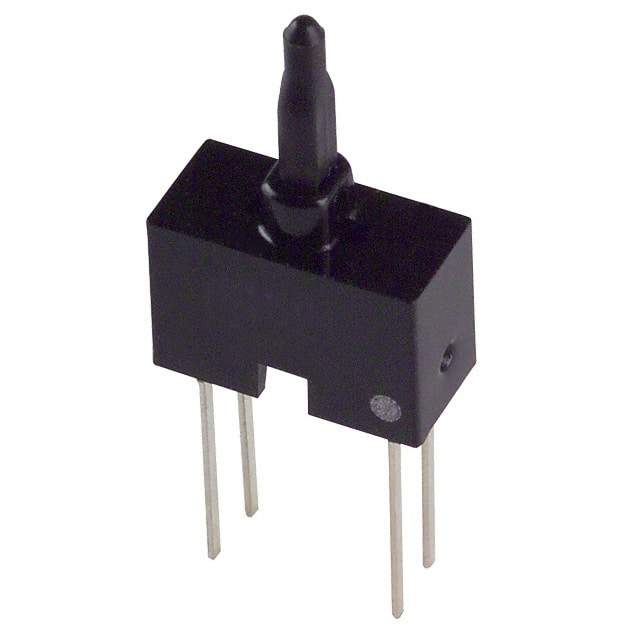

Detailed Pin Configuration

- V+

- Inverting Input (-)

- Non-inverting Input (+)

- V-

- Output

Functional Features

- High gain of 100dB

- Low input bias current for precision applications

- Wide supply voltage range for versatility

- Small package size for space-constrained designs

Advantages and Disadvantages

Advantages: - High gain allows for signal amplification in low-level applications - Low input bias current enables use in precision measurement systems - Wide supply voltage range provides flexibility in power supply design

Disadvantages: - Limited output current may not be suitable for high-power applications - Operating temperature range may restrict use in extreme environments

Working Principles

The EE-SA105 is a voltage feedback operational amplifier designed to amplify small signals with high precision. It utilizes internal compensation to achieve stable operation over a wide range of operating conditions.

Detailed Application Field Plans

The EE-SA105 is well-suited for use in: - Sensor signal conditioning - Instrumentation amplifiers - Active filters - Precision voltage amplification

Detailed and Complete Alternative Models

- EE-SB110: Higher gain bandwidth product for wider frequency response

- EE-SC95: Lower input bias current for ultra-precision applications

- EE-SD120: Higher output current capability for driving loads

In conclusion, the EE-SA105 is a versatile operational amplifier offering high gain and precision performance in a compact package. Its wide application field plans and availability of alternative models make it a popular choice for various electronic designs.

(Word count: 298)

技術ソリューションにおける EE-SA105 の適用に関連する 10 件の一般的な質問と回答をリストします。

What is EE-SA105?

- EE-SA105 is a standard specification for electronic equipment environmental testing, which outlines the procedures and requirements for testing the environmental performance of electronic equipment.

Why is EE-SA105 important in technical solutions?

- EE-SA105 is important because it ensures that electronic equipment can withstand various environmental conditions, such as temperature, humidity, and vibration, which is crucial for reliable operation in real-world applications.

What types of tests are included in EE-SA105?

- EE-SA105 includes tests for temperature cycling, humidity exposure, vibration, shock, and other environmental factors to assess the durability and reliability of electronic equipment.

How does EE-SA105 impact product development?

- EE-SA105 guides product developers in designing electronic equipment that meets environmental performance standards, leading to more robust and reliable technical solutions.

What are the benefits of complying with EE-SA105?

- Compliance with EE-SA105 ensures that electronic equipment can perform effectively in diverse environmental conditions, reducing the risk of failure and increasing customer satisfaction.

Are there any specific requirements for documentation under EE-SA105?

- Yes, EE-SA105 requires comprehensive documentation of test procedures, results, and analysis to demonstrate compliance with environmental testing standards.

How can I ensure my technical solution complies with EE-SA105?

- To ensure compliance, it's essential to conduct thorough environmental testing according to the specifications outlined in EE-SA105 and document the results accurately.

What are some common challenges in meeting EE-SA105 requirements?

- Common challenges include designing equipment that can withstand extreme environmental conditions, conducting accurate and repeatable tests, and interpreting complex testing criteria.

Can EE-SA105 be applied to both consumer and industrial electronic equipment?

- Yes, EE-SA105 can be applied to a wide range of electronic equipment, including consumer electronics, industrial machinery, and communication systems.

How often should environmental testing according to EE-SA105 be conducted?

- Environmental testing should be conducted at various stages of product development, including during initial design, prototype testing, and production, to ensure ongoing compliance with EE-SA105 standards.