IXGH24N120C3H1

Introduction

The IXGH24N120C3H1 is a high-power insulated gate bipolar transistor (IGBT) designed for various power electronic applications. This entry provides an overview of the product, including its basic information, specifications, detailed pin configuration, functional features, advantages and disadvantages, working principles, application field plans, and alternative models.

Basic Information Overview

- Category: Power Semiconductor

- Use: High-power switching applications

- Characteristics: High current and voltage handling capability, low conduction losses, fast switching speed

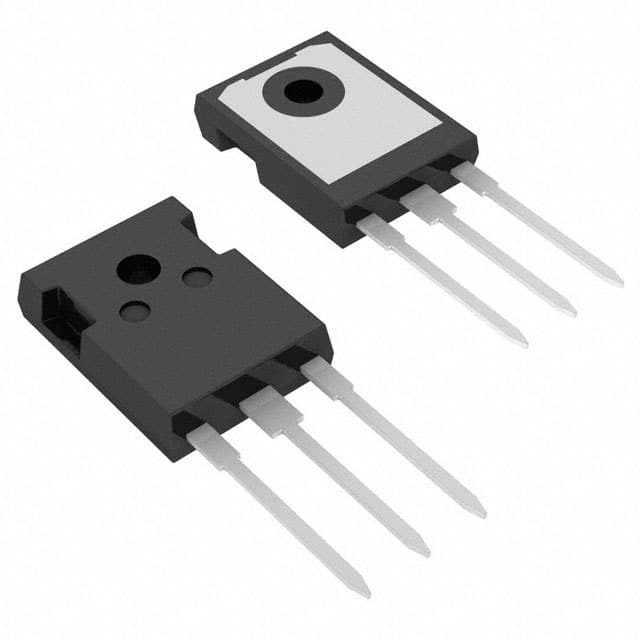

- Package: TO-247

- Essence: High-power IGBT for efficient power conversion

- Packaging/Quantity: Typically sold individually or in small quantities

Specifications

- Voltage Rating: 1200V

- Current Rating: 24A

- Maximum Operating Temperature: 150°C

- Gate-Emitter Voltage: ±20V

- Collector-Emitter Saturation Voltage: 2.2V at 24A

Detailed Pin Configuration

The IXGH24N120C3H1 follows the standard pin configuration for TO-247 packages: 1. Collector (C) 2. Gate (G) 3. Emitter (E)

Functional Features

- High current and voltage handling capability

- Low conduction losses

- Fast switching speed

- Built-in freewheeling diode for inductive load protection

Advantages and Disadvantages

Advantages

- Efficient power conversion

- Suitable for high-power applications

- Low on-state voltage drop

Disadvantages

- Higher cost compared to standard power transistors

- Requires careful thermal management due to high power dissipation

Working Principles

The IXGH24N120C3H1 operates based on the principles of IGBT technology, where it combines the advantages of MOSFETs and bipolar junction transistors. During operation, the IGBT controls the flow of current between the collector and emitter terminals by modulating the gate signal.

Detailed Application Field Plans

The IXGH24N120C3H1 finds extensive use in various high-power applications, including: - Motor drives - Renewable energy systems - Uninterruptible power supplies (UPS) - Induction heating systems - Welding equipment

Detailed and Complete Alternative Models

- IXGH24N100C3: Lower voltage rating with similar current handling capability

- IXGH30N60B: Higher current rating with slightly lower voltage rating

- IXGH40N60C2D1: Higher voltage and current rating for ultra-high-power applications

In conclusion, the IXGH24N120C3H1 is a high-power IGBT suitable for demanding power electronic applications, offering efficient power conversion and high reliability.

Word count: 366

技術ソリューションにおける IXGH24N120C3H1 の適用に関連する 10 件の一般的な質問と回答をリストします。

What is the maximum voltage rating of IXGH24N120C3H1?

- The maximum voltage rating of IXGH24N120C3H1 is 1200V.

What is the maximum current rating of IXGH24N120C3H1?

- The maximum current rating of IXGH24N120C3H1 is 24A.

What type of package does IXGH24N120C3H1 come in?

- IXGH24N120C3H1 comes in a TO-247 package.

What are the typical applications for IXGH24N120C3H1?

- IXGH24N120C3H1 is commonly used in applications such as motor drives, inverters, and power supplies.

Does IXGH24N120C3H1 have built-in protection features?

- Yes, IXGH24N120C3H1 has built-in short-circuit protection and overcurrent protection.

What is the operating temperature range of IXGH24N120C3H1?

- The operating temperature range of IXGH24N120C3H1 is -55°C to 150°C.

Is IXGH24N120C3H1 suitable for high-frequency switching applications?

- Yes, IXGH24N120C3H1 is suitable for high-frequency switching due to its fast switching characteristics.

What is the gate charge of IXGH24N120C3H1?

- The gate charge of IXGH24N120C3H1 is typically 80nC.

Can IXGH24N120C3H1 be used in parallel configurations for higher current applications?

- Yes, IXGH24N120C3H1 can be used in parallel configurations to achieve higher current ratings.

Are there any recommended heat sink solutions for IXGH24N120C3H1?

- Yes, it is recommended to use a suitable heat sink to maintain the junction temperature within safe limits during operation.