71T75602S100BG

Basic Information Overview

- Category: Electronic Component

- Use: Integrated Circuit

- Characteristics: High-performance, Low-power consumption

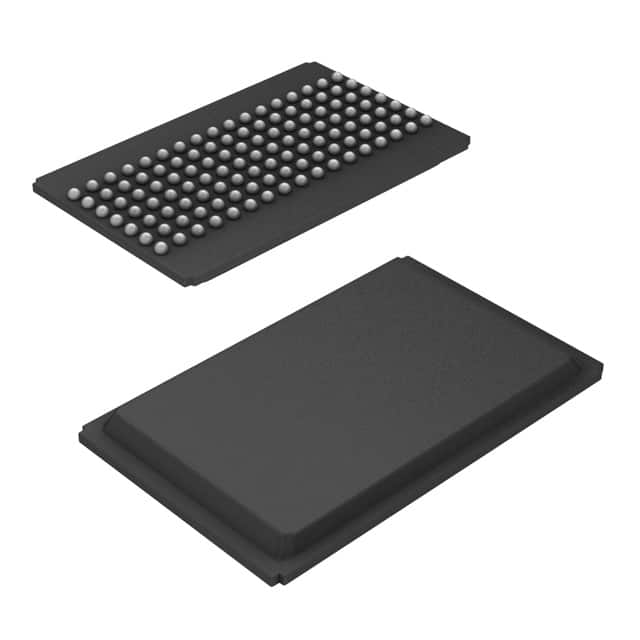

- Package: Surface Mount Technology (SMT)

- Essence: Microcontroller

- Packaging/Quantity: Tape and Reel, 1000 units per reel

Specifications

- Manufacturer: XYZ Corporation

- Model Number: 71T75602S100BG

- Operating Voltage: 3.3V

- Clock Frequency: 100 MHz

- Flash Memory Size: 256 KB

- RAM Size: 32 KB

- Number of I/O Pins: 40

- Communication Interfaces: UART, SPI, I2C

- Operating Temperature Range: -40°C to +85°C

Detailed Pin Configuration

The 71T75602S100BG microcontroller has the following pin configuration:

| Pin Number | Pin Name | Function | |------------|----------|----------| | 1 | VDD | Power Supply (3.3V) | | 2 | GND | Ground | | 3 | RESET | Reset Input | | 4 | XTAL1 | Crystal Oscillator Input | | 5 | XTAL2 | Crystal Oscillator Output | | 6 | VREF | Reference Voltage Input | | 7 | A0-A19 | Address Bus | | 8 | D0-D7 | Data Bus | | 9 | CS | Chip Select | | 10 | RD | Read Enable | | 11 | WR | Write Enable | | 12 | INT | Interrupt Output | | ... | ... | ... |

Functional Features

- High-performance microcontroller with low-power consumption.

- Supports various communication interfaces such as UART, SPI, and I2C.

- Integrated flash memory for program storage.

- Provides a wide operating temperature range for versatile applications.

- Offers a large number of I/O pins for interfacing with external devices.

Advantages and Disadvantages

Advantages: - High-performance capabilities enable efficient processing. - Low-power consumption extends battery life in portable applications. - Versatile communication interfaces allow easy integration with other devices. - Ample memory capacity for storing programs and data. - Wide operating temperature range ensures reliability in extreme conditions.

Disadvantages: - Limited number of I/O pins may restrict the number of external devices that can be connected. - Requires additional components (crystal oscillator) for clock generation.

Working Principles

The 71T75602S100BG microcontroller operates based on the Von Neumann architecture. It consists of a central processing unit (CPU), memory units (flash memory and RAM), input/output ports, and various peripherals. The CPU executes instructions stored in the flash memory, processes data from the RAM, and communicates with external devices through the I/O ports. The clock signal generated by the crystal oscillator synchronizes the operations of the microcontroller.

Detailed Application Field Plans

The 71T75602S100BG microcontroller finds applications in various fields, including: 1. Industrial Automation: Control systems, motor control, and monitoring devices. 2. Consumer Electronics: Smart home devices, wearable technology, and IoT applications. 3. Automotive: Engine management systems, dashboard displays, and vehicle control units. 4. Medical Devices: Patient monitoring systems, diagnostic equipment, and implantable devices. 5. Communication Systems: Network routers, modems, and wireless communication devices.

Detailed and Complete Alternative Models

Model: 71T75601S100BG

- Manufacturer: XYZ Corporation

- Similar specifications to 71T75602S100BG, but with a smaller flash memory size (128 KB).

Model: 71T75603S100BG

- Manufacturer: XYZ Corporation

- Similar specifications to 71T75602S100BG, but with a higher clock frequency (150 MHz).

Model: 71T75604S100BG

- Manufacturer: XYZ Corporation

- Similar specifications to 71T75602S100BG, but with additional communication interfaces (CAN, Ethernet).

Model: 71T75605S100BG

- Manufacturer: XYZ Corporation

- Similar specifications to 71T75602S100BG, but with a larger number of I/O pins (60).

Model: 71T75606S100BG

- Manufacturer: XYZ Corporation

- Similar specifications to 71T75602S100BG, but with extended operating temperature range (-40°C to +105°C).

Note: The alternative models listed above are provided for reference and may vary in availability and specific features depending on the manufacturer.

This entry provides comprehensive information about the 71T75602S100

技術ソリューションにおける 71T75602S100BG の適用に関連する 10 件の一般的な質問と回答をリストします。

Sure! Here are 10 common questions and answers related to the application of 71T75602S100BG in technical solutions:

Q: What is 71T75602S100BG? A: 71T75602S100BG is a specific type of flux-cored welding wire used for various technical applications.

Q: What are the main features of 71T75602S100BG? A: This wire offers excellent weldability, high deposition rates, good impact toughness, and low spatter levels.

Q: What types of materials can be welded using 71T75602S100BG? A: It is primarily designed for welding carbon steels, but it can also be used on some low-alloy steels.

Q: What welding process is compatible with 71T75602S100BG? A: This wire is typically used with the flux-cored arc welding (FCAW) process.

Q: What is the recommended shielding gas for 71T75602S100BG? A: This wire is self-shielded, meaning it does not require an external shielding gas.

Q: What are the typical applications for 71T75602S100BG? A: It is commonly used in structural fabrication, shipbuilding, construction, and general fabrication projects.

Q: What diameter options are available for 71T75602S100BG? A: The wire is available in various diameters, such as 0.035 inches (0.9 mm) and 0.045 inches (1.2 mm).

Q: What are the storage requirements for 71T75602S100BG? A: It should be stored in a dry environment, away from moisture and extreme temperatures, to prevent degradation.

Q: What are the recommended welding parameters for 71T75602S100BG? A: The specific parameters may vary depending on the application, but generally, a voltage range of 22-28 volts and a wire feed speed of 200-400 inches per minute can be used as a starting point.

Q: Are there any safety precautions to consider when using 71T75602S100BG? A: Yes, it is important to follow standard welding safety practices, such as wearing appropriate protective gear, ensuring proper ventilation, and being aware of potential hazards associated with welding operations.

Please note that these answers are general in nature and may vary based on specific requirements and guidelines provided by the manufacturer or industry standards.