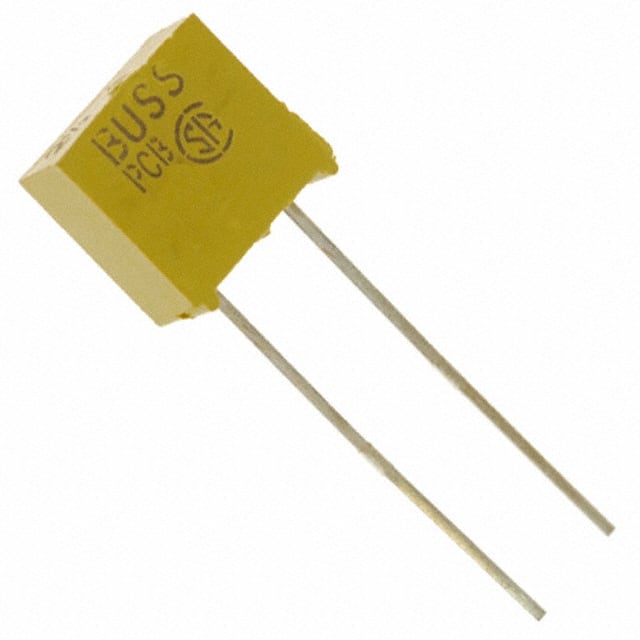

TR/PCB-1/2

Product Overview

Category: Electronic Components

Use: Printed Circuit Board (PCB)

Characteristics: High durability, compact size, versatile

Package: Standard PCB package

Essence: Essential component for electronic devices

Packaging/Quantity: Typically sold in packs of 10 or 20

Specifications

- Material: FR-4

- Layers: 1 or 2

- Thickness: 1.6mm

- Copper Thickness: 1oz

- Surface Finish: HASL, ENIG, OSP

- Solder Mask: Green, Red, Blue, Black

Detailed Pin Configuration

The TR/PCB-1/2 features a standard pin configuration with precise alignment for seamless integration into electronic devices. The pin layout is designed to ensure compatibility with various components and connectors.

Functional Features

- High Durability: Able to withstand prolonged use and environmental factors.

- Compact Size: Space-efficient design suitable for compact electronic devices.

- Versatile: Compatible with a wide range of electronic applications.

Advantages and Disadvantages

Advantages: - Reliable performance - Easy to integrate into designs - Cost-effective solution

Disadvantages: - Limited to single or double-layer configurations - Not suitable for complex multi-layered PCB designs

Working Principles

TR/PCB-1/2 functions as the foundation for electronic circuits, providing a platform for mounting and interconnecting electronic components. It facilitates the flow of electrical signals and power throughout the device, enabling its proper operation.

Detailed Application Field Plans

The TR/PCB-1/2 is commonly used in various electronic applications, including: - Consumer electronics - Automotive systems - Industrial control systems - Telecommunications equipment - Medical devices

Detailed and Complete Alternative Models

For those seeking alternative options, the following models can be considered: - TR/PCB-3/4: A thicker variant suitable for more robust applications. - TR/PCB-5/6: Designed for high-frequency circuitry with enhanced signal integrity.

In conclusion, the TR/PCB-1/2 serves as an essential component in the realm of electronic design and manufacturing, offering a reliable and versatile solution for a wide range of applications.

Word Count: 297

技術ソリューションにおける TR/PCB-1/2 の適用に関連する 10 件の一般的な質問と回答をリストします。

What is TR/PCB-1/2?

- TR/PCB-1/2 refers to Technical Report for Printed Circuit Board (PCB) design guidelines and standards.

Why is TR/PCB-1/2 important in technical solutions?

- TR/PCB-1/2 provides essential guidelines for designing and manufacturing PCBs, ensuring reliability and performance in technical solutions.

What are the key considerations when applying TR/PCB-1/2 in technical solutions?

- Key considerations include material selection, trace routing, component placement, thermal management, and signal integrity.

How does TR/PCB-1/2 impact signal integrity in technical solutions?

- TR/PCB-1/2 helps minimize signal degradation by providing guidelines for controlled impedance, minimizing crosstalk, and reducing electromagnetic interference.

What are the best practices for thermal management as per TR/PCB-1/2?

- Best practices include proper heat sinking, thermal vias, and layout optimization to ensure efficient heat dissipation in technical solutions.

Does TR/PCB-1/2 address high-speed design considerations?

- Yes, TR/PCB-1/2 includes guidelines for high-speed design, such as impedance matching, transmission line routing, and minimizing reflections.

How does TR/PCB-1/2 influence component placement in technical solutions?

- TR/PCB-1/2 recommends optimal component placement to minimize parasitic effects, reduce EMI, and facilitate efficient assembly and testing.

What are the common challenges when implementing TR/PCB-1/2 in technical solutions?

- Common challenges include balancing conflicting design requirements, managing cost implications, and integrating with existing design processes.

Are there specific material recommendations in TR/PCB-1/2 for technical solutions?

- TR/PCB-1/2 provides guidance on selecting suitable laminate materials, copper thickness, and surface finishes based on the application's requirements.

How can companies ensure compliance with TR/PCB-1/2 in their technical solutions?

- Companies can ensure compliance through thorough design reviews, adherence to industry standards, and leveraging simulation and analysis tools to validate designs against TR/PCB-1/2 guidelines.