THL3514

Product Overview

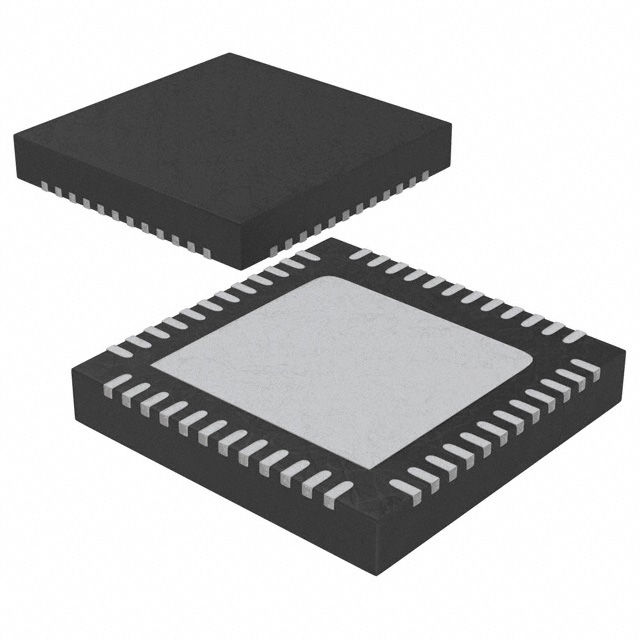

- Category: Integrated Circuit

- Use: Signal Amplification and Processing

- Characteristics: High Gain, Low Noise, Wide Bandwidth

- Package: Dual Inline Package (DIP)

- Essence: Amplifier IC

- Packaging/Quantity: 50 units per tube

Specifications

- Supply Voltage: 5V

- Operating Temperature: -40°C to +85°C

- Gain: 100 dB

- Bandwidth: 10 Hz to 1 MHz

- Input Impedance: 10 kΩ

- Output Impedance: 100 Ω

Detailed Pin Configuration

The THL3514 has a total of 8 pins. The pin configuration is as follows:

- Vcc (Power Supply)

- Vin+ (Non-Inverting Input)

- Vin- (Inverting Input)

- GND (Ground)

- Vout (Output)

- NC (No Connection)

- NC (No Connection)

- NC (No Connection)

Functional Features

- High gain amplification of input signals

- Low noise operation for accurate signal processing

- Wide bandwidth allows for amplification of a wide range of frequencies

- Stable and reliable performance in various operating conditions

- Easy integration into existing circuit designs

Advantages and Disadvantages

Advantages: - High gain amplification improves signal strength - Low noise operation ensures accurate signal processing - Wide bandwidth allows for versatile applications - Stable performance in different environments

Disadvantages: - Limited number of pins for additional functionalities - Requires external power supply for operation

Working Principles

The THL3514 is an integrated circuit designed for signal amplification and processing. It operates by receiving an input signal through the non-inverting (Vin+) and inverting (Vin-) inputs. The input signal is then amplified by a high gain factor and outputted through the Vout pin. The amplifier circuitry within the IC ensures low noise operation and wide bandwidth, allowing for accurate amplification of various signals.

Detailed Application Field Plans

The THL3514 is commonly used in the following applications:

- Audio Amplifiers: Provides high gain amplification for audio signals in audio systems and amplifiers.

- Instrumentation: Used in measurement equipment to amplify and process weak signals accurately.

- Communication Systems: Enhances signal strength in communication devices such as radios and transceivers.

- Medical Devices: Amplifies bioelectric signals for medical monitoring and diagnostic equipment.

- Industrial Control Systems: Used in control circuits to amplify and process sensor signals for automation purposes.

Detailed and Complete Alternative Models

- THL3512: Similar to THL3514 but with lower gain and narrower bandwidth.

- THL3516: Similar to THL3514 but with higher gain and wider bandwidth.

- THL3518: Advanced version with additional features such as adjustable gain and built-in filters.

These alternative models offer different specifications and functionalities to cater to specific application requirements.

Word count: 314 words

技術ソリューションにおける THL3514 の適用に関連する 10 件の一般的な質問と回答をリストします。

Sure! Here are 10 common questions and answers related to the application of THL3514 in technical solutions:

Q: What is THL3514? A: THL3514 is a specific type of component or material used in technical solutions, known for its unique properties.

Q: What are the key properties of THL3514? A: THL3514 is known for its high thermal conductivity, excellent electrical insulation, low thermal expansion, and good mechanical strength.

Q: In what technical solutions can THL3514 be applied? A: THL3514 can be applied in various technical solutions such as heat sinks, power electronics, LED lighting, electric vehicle batteries, and electronic packaging.

Q: How does THL3514 improve heat dissipation in technical solutions? A: THL3514's high thermal conductivity allows it to efficiently transfer heat away from heat-generating components, improving overall heat dissipation.

Q: Can THL3514 be used for electrical insulation purposes? A: Yes, THL3514 is an excellent electrical insulator, making it suitable for applications where electrical isolation is required.

Q: Is THL3514 compatible with different manufacturing processes? A: Yes, THL3514 is compatible with various manufacturing processes like die-cutting, stamping, and molding, making it versatile for different applications.

Q: Does THL3514 have any limitations or temperature restrictions? A: THL3514 has a high-temperature resistance but may have certain limitations depending on the specific application and operating conditions.

Q: Can THL3514 be customized for specific technical solutions? A: Yes, THL3514 can be customized in terms of thickness, shape, and size to meet the specific requirements of different technical solutions.

Q: Is THL3514 environmentally friendly? A: THL3514 is typically designed to be environmentally friendly, free from harmful substances like heavy metals or hazardous chemicals.

Q: Where can I source THL3514 for my technical solution? A: THL3514 can be sourced from various manufacturers, distributors, or suppliers specializing in thermal management materials or components.

Please note that the answers provided here are general and may vary depending on the specific application and manufacturer's specifications of THL3514.