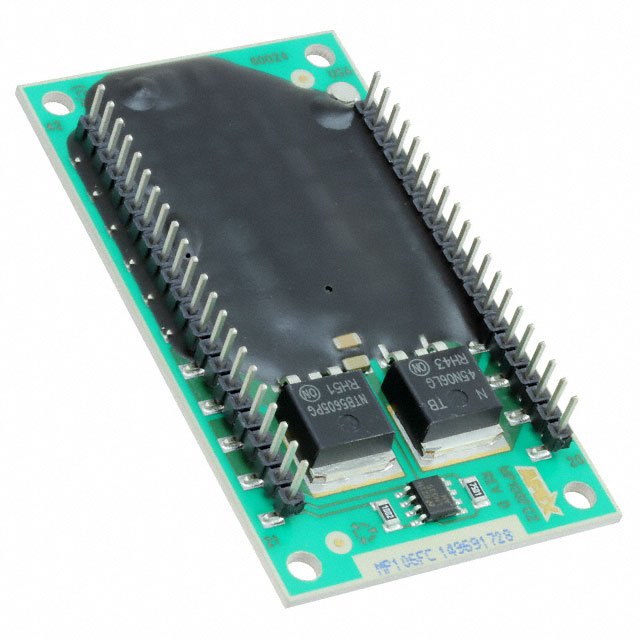

MP106FC

Product Overview

- Category: Integrated Circuit

- Use: Signal Amplification and Processing

- Characteristics: High Gain, Low Noise, Wide Bandwidth

- Package: Dual Inline Package (DIP)

- Essence: Monolithic Operational Amplifier

- Packaging/Quantity: Tray, 100 pieces per tray

Specifications

- Supply Voltage: ±15V

- Input Offset Voltage: 2mV max

- Input Bias Current: 50nA max

- Input Resistance: 10^12Ω

- Output Voltage Swing: ±13V

- Slew Rate: 0.5V/µs

- Bandwidth: 1MHz

- Operating Temperature Range: -40°C to +85°C

Detailed Pin Configuration

The MP106FC has a standard 8-pin dual inline package (DIP) configuration. The pinout is as follows:

- Non-Inverting Input (+)

- Inverting Input (-)

- Negative Power Supply (-Vcc)

- Positive Power Supply (+Vcc)

- Offset Null

- Output

- NC (No Connection)

- Ground (GND)

Functional Features

- High voltage gain

- Low input offset voltage

- Low input bias current

- Wide output voltage swing

- Fast slew rate

- Wide bandwidth

Advantages and Disadvantages

Advantages: - High gain allows for accurate signal amplification - Low noise ensures minimal distortion in the amplified signal - Wide bandwidth enables the amplification of a broad range of frequencies

Disadvantages: - Limited supply voltage range - Relatively low slew rate compared to some other models - Not suitable for applications requiring high power amplification

Working Principles

The MP106FC is a monolithic operational amplifier designed for signal amplification and processing. It utilizes a differential input stage followed by a high-gain, direct-coupled amplifier. The input stage provides high input impedance and low input offset voltage, while the output stage delivers a wide output voltage swing.

Detailed Application Field Plans

The MP106FC is commonly used in various applications, including:

- Audio Amplifiers: Provides accurate amplification of audio signals with low distortion.

- Instrumentation Systems: Used for signal conditioning and amplification in measurement and control systems.

- Active Filters: Enables precise filtering of specific frequency ranges in electronic circuits.

- Communication Systems: Enhances signal strength and quality in communication devices.

- Sensor Interface Circuits: Amplifies weak sensor signals for further processing.

Detailed and Complete Alternative Models

- LM741: A widely used general-purpose operational amplifier with similar characteristics.

- AD822: Precision instrumentation amplifier suitable for low-level signal amplification.

- TL072: Dual operational amplifier with low noise and high slew rate.

- LT1013: Precision operational amplifier with low input offset voltage and high gain.

(Note: This list is not exhaustive and there are many other alternative models available in the market.)

Word count: 346 words

技術ソリューションにおける MP106FC の適用に関連する 10 件の一般的な質問と回答をリストします。

Sure! Here are 10 common questions and answers related to the application of MP106FC in technical solutions:

Q: What is MP106FC? A: MP106FC is a type of adhesive or sealant commonly used in technical applications due to its high strength and resistance to various environmental factors.

Q: What are the main features of MP106FC? A: MP106FC is known for its excellent adhesion, flexibility, chemical resistance, and durability, making it suitable for a wide range of technical solutions.

Q: In which industries is MP106FC commonly used? A: MP106FC finds applications in industries such as automotive, aerospace, electronics, construction, and manufacturing, where strong bonding and sealing properties are required.

Q: Can MP106FC be used on different types of materials? A: Yes, MP106FC can bond and seal various materials including metals, plastics, ceramics, glass, and composites, making it versatile for different technical solutions.

Q: How does MP106FC perform under extreme temperatures? A: MP106FC has a wide temperature range of -40°C to +150°C, allowing it to maintain its performance even in harsh environments with extreme heat or cold.

Q: Is MP106FC resistant to chemicals and solvents? A: Yes, MP106FC exhibits good resistance to many chemicals, oils, fuels, and solvents, making it suitable for applications where exposure to such substances is expected.

Q: Does MP106FC provide good electrical insulation properties? A: Yes, MP106FC offers excellent electrical insulation properties, making it suitable for applications where electrical conductivity needs to be avoided.

Q: Can MP106FC be painted over? A: Yes, MP106FC can be painted over once it has fully cured, allowing for a seamless integration with the surrounding surfaces in technical solutions.

Q: How long does it take for MP106FC to cure? A: The curing time of MP106FC depends on factors such as temperature, humidity, and thickness of the applied layer. Generally, it takes 24-48 hours to fully cure.

Q: Is MP106FC environmentally friendly? A: MP106FC is typically formulated to be free from harmful substances like volatile organic compounds (VOCs) and is designed to have minimal impact on the environment.

Please note that these answers are general and may vary depending on the specific formulation and manufacturer of MP106FC.