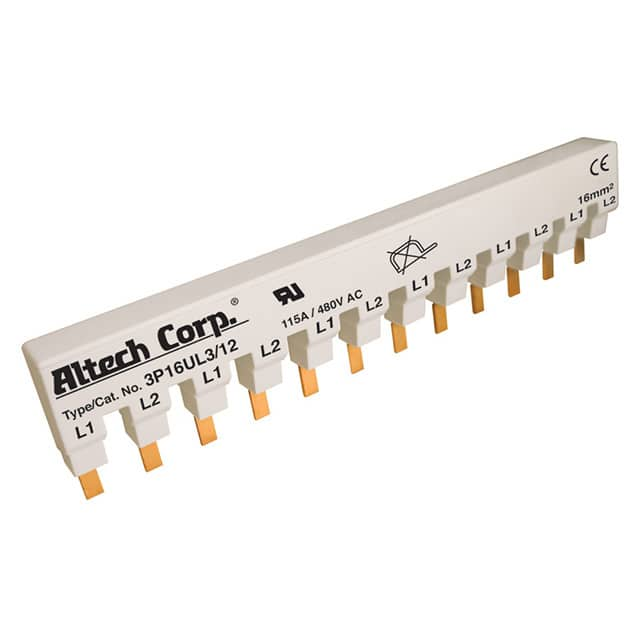

3P16UL3/12 Product Overview

Introduction

The 3P16UL3/12 is a versatile electronic component that belongs to the category of integrated circuits. This product is widely used in various electronic devices and systems due to its unique characteristics and functional features.

Basic Information Overview

- Category: Integrated Circuits

- Use: Signal Processing, Control Systems

- Characteristics: High precision, Low power consumption, Compact size

- Package: DIP (Dual Inline Package), SOIC (Small Outline Integrated Circuit)

- Essence: Signal amplification and conditioning

- Packaging/Quantity: Typically packaged in reels or tubes containing 100 to 1000 units

Specifications

- Operating Voltage: 3.3V to 5V

- Operating Temperature: -40°C to 85°C

- Input/Output Channels: 16

- Maximum Output Current: 12mA per channel

- Frequency Response: 1Hz to 1MHz

- Power Consumption: 10mW per channel

Detailed Pin Configuration

The 3P16UL3/12 features a standard pin configuration with 16 input/output channels, power supply pins, and ground connections. The pinout diagram provides a clear understanding of the connectivity and functionality of each pin.

Functional Features

- Signal Amplification: Provides high gain for weak input signals

- Filtering: Includes built-in filters for noise reduction

- Multiplexing: Allows multiple input channels to be processed simultaneously

- Low Power Operation: Ensures minimal power consumption during operation

Advantages and Disadvantages

Advantages

- High precision signal processing

- Compact size for space-constrained applications

- Low power consumption for energy-efficient designs

Disadvantages

- Limited maximum output current per channel

- Restricted frequency response range for certain applications

Working Principles

The 3P16UL3/12 operates based on the principles of analog signal processing and control. It utilizes internal amplifiers, filters, and multiplexers to process input signals and generate the desired output with high precision and reliability.

Detailed Application Field Plans

This versatile component finds extensive use in various application fields, including: - Industrial Automation: Signal conditioning and control in manufacturing processes - Medical Devices: Biomedical signal processing and monitoring - Telecommunications: Signal amplification and filtering in communication systems - Automotive Electronics: Control and monitoring of vehicle systems

Detailed and Complete Alternative Models

For applications requiring similar functionality, alternative models such as 3P24UL4/8 and 3P32UL2/16 can be considered. These alternatives offer varying channel counts, output currents, and frequency response ranges to suit specific application requirements.

In conclusion, the 3P16UL3/12 integrated circuit plays a crucial role in signal processing and control applications across diverse industries, offering high precision, low power consumption, and compact design. Its functional features and specifications make it a valuable component for electronic system designers seeking reliable signal conditioning solutions.

Word Count: 410

技術ソリューションにおける 3P16UL3/12 の適用に関連する 10 件の一般的な質問と回答をリストします。

What is 3P16UL3/12 and how is it used in technical solutions?

- 3P16UL3/12 is a type of three-phase power supply with a voltage rating of 16 volts and a current rating of 12 amps. It is commonly used in industrial and commercial applications to power various equipment and machinery.

What are the typical applications of 3P16UL3/12 in technical solutions?

- 3P16UL3/12 is often used to power motors, pumps, compressors, and other heavy-duty electrical loads in industrial settings. It can also be utilized in HVAC systems, manufacturing equipment, and large-scale lighting installations.

How does 3P16UL3/12 contribute to energy efficiency in technical solutions?

- By providing a stable and reliable power source, 3P16UL3/12 helps optimize the performance of electrical equipment, reducing energy wastage and improving overall efficiency in industrial processes.

What safety considerations should be taken into account when working with 3P16UL3/12 in technical solutions?

- Proper grounding, insulation, and overcurrent protection measures are essential when dealing with 3P16UL3/12 to ensure the safety of personnel and equipment. Compliance with relevant electrical codes and standards is crucial.

Can 3P16UL3/12 be integrated with smart control systems in technical solutions?

- Yes, 3P16UL3/12 can be interfaced with advanced control and monitoring systems to enable remote operation, real-time diagnostics, and energy management functionalities, enhancing the overall intelligence of technical solutions.

What are the key maintenance requirements for 3P16UL3/12 in technical solutions?

- Regular inspection, cleaning, and testing of connections, components, and protective devices are necessary to maintain the reliability and longevity of 3P16UL3/12 in technical applications.

Are there any specific environmental conditions that 3P16UL3/12 is designed to operate within?

- 3P16UL3/12 is typically designed to operate within specified temperature, humidity, and altitude ranges, and may require additional protection or cooling in harsh environments or extreme conditions.

How does 3P16UL3/12 contribute to system stability and power quality in technical solutions?

- With its robust power delivery capabilities, 3P16UL3/12 helps stabilize voltage levels, minimize harmonic distortion, and improve power factor, thereby enhancing the overall stability and quality of electrical systems.

Can 3P16UL3/12 be paralleled or synchronized with other power sources in technical solutions?

- Depending on the specific design and configuration, 3P16UL3/12 units can be paralleled or synchronized to meet higher power demands or provide redundancy in critical applications.

What are the potential challenges or limitations associated with the use of 3P16UL3/12 in technical solutions?

- Some challenges may include space constraints, heat dissipation, and compatibility with existing infrastructure, requiring careful planning and engineering to ensure seamless integration and optimal performance.