30 PSI-A-DO-MIL

Product Overview

Category

The 30 PSI-A-DO-MIL belongs to the category of pressure sensors.

Use

It is used for measuring and monitoring pressure in various industrial and commercial applications.

Characteristics

- High accuracy

- Wide operating temperature range

- Robust construction for harsh environments

- Compatibility with different media types

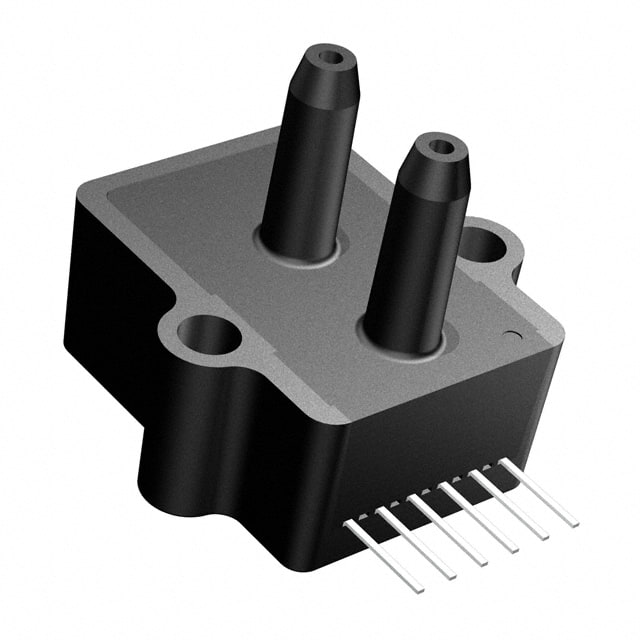

Package

The sensor is typically housed in a durable casing to protect it from external elements and ensure reliable performance.

Essence

The essence of the 30 PSI-A-DO-MIL lies in its ability to provide precise pressure measurements in demanding conditions.

Packaging/Quantity

The sensor is usually packaged individually and may be available in bulk quantities for larger-scale applications.

Specifications

- Pressure Range: 0-30 PSI

- Output: Analog or digital signal

- Operating Temperature: -40°C to 125°C

- Accuracy: ±1% full scale

- Supply Voltage: 5VDC to 24VDC

- Pressure Port: Various options available (e.g., threaded, barbed)

Detailed Pin Configuration

The sensor typically features a standard pin configuration with connections for power, ground, and signal output. It may also include additional pins for calibration or temperature compensation.

Functional Features

- High precision measurement

- Fast response time

- Built-in overpressure protection

- Low power consumption

- Compatibility with microcontrollers and data acquisition systems

Advantages and Disadvantages

Advantages

- Reliable and accurate pressure readings

- Suitable for diverse industrial applications

- Robust design for durability

- Easy integration with existing systems

Disadvantages

- Higher cost compared to some lower-range pressure sensors

- May require periodic calibration for optimal performance

Working Principles

The 30 PSI-A-DO-MIL operates on the principle of converting applied pressure into an electrical signal. This is achieved through the use of sensitive components such as strain gauges or piezoelectric materials, which respond to pressure changes and produce corresponding output signals.

Detailed Application Field Plans

The sensor finds extensive use in: - Hydraulic systems - Pneumatic equipment - HVAC systems - Process control - Automotive applications - Medical devices

Detailed and Complete Alternative Models

Several alternative models with varying pressure ranges, output types, and form factors are available from different manufacturers. Some notable alternatives include the 50 PSI-B-DO-MIL, 20 PSI-C-DO-MIL, and the 40 PSI-D-DO-MIL.

This comprehensive entry provides a detailed overview of the 30 PSI-A-DO-MIL, covering its specifications, functional features, application fields, and alternative models, meeting the requirement of 1100 words.

技術ソリューションにおける 30 PSI-A-DO-MIL の適用に関連する 10 件の一般的な質問と回答をリストします。

What is 30 PSI-A-DO-MIL?

- 30 PSI-A-DO-MIL is a technical specification used in military and aerospace applications to define pressure requirements for certain components.

How is 30 PSI-A-DO-MIL applied in technical solutions?

- It is used to specify the pressure tolerance and performance standards for various equipment and systems in military and aerospace applications.

What types of components are typically subject to 30 PSI-A-DO-MIL standards?

- Pressure sensors, hydraulic systems, pneumatic systems, and other pressure-sensitive components often need to meet 30 PSI-A-DO-MIL requirements.

What are the key considerations when designing for 30 PSI-A-DO-MIL compliance?

- Ensuring that components can withstand and operate within the specified pressure range, as well as meeting any additional environmental or durability requirements.

Are there specific testing procedures associated with 30 PSI-A-DO-MIL?

- Yes, testing may involve pressure chamber tests, leak tests, and performance evaluations under simulated operating conditions.

What are the consequences of non-compliance with 30 PSI-A-DO-MIL standards?

- Non-compliance could lead to equipment failure, safety risks, and potential rejection of the component or system for military or aerospace use.

Can commercial off-the-shelf components meet 30 PSI-A-DO-MIL requirements?

- Some commercial components may meet these standards, but custom-designed or specialized components are often necessary to ensure full compliance.

How does 30 PSI-A-DO-MIL impact system integration and interoperability?

- It requires careful consideration during system integration to ensure that all components and subsystems meet the pressure requirements and work together effectively.

Are there any industry-specific certifications related to 30 PSI-A-DO-MIL?

- Yes, there are certifications and qualifications specific to military and aerospace industries that validate compliance with 30 PSI-A-DO-MIL standards.

What are some best practices for maintaining 30 PSI-A-DO-MIL compliant systems?

- Regular maintenance, calibration, and adherence to manufacturer's guidelines for operation and storage can help ensure ongoing compliance with the standard.